The engine valves of automobile directly affect the engine seal and related performance. The working environment is harsh, and it is affected by strong mechanical load, high temperature and chemical corrosion. It is an important part of the engine and must be installed correctly. Avoid knock against during transportation, shall not overload and bear additional force during use, otherwise the valve will be deformation failure, leading to early damage. So please refer to the following considerations when install the valves.

1、 After the new guide is installed in the cylinder head, should correct the roundness and inner hole size of guide by reamer, let the clearance between valve stem and guide meet the requirements of the engine manual. During the use, the above clearance must not be exceeded the wear limit of the engine manual. When the clearance reach to 0.13mm (stem diameter is below 8mm) or 0.16mm (stem diameter is over 8mm), should replace the valve or guide, otherwise leading to the valve damage.

2、 Engine valves of different models in the same series may be difference, do not mix-installation.

3、 Valve seat for deformation or burns must be corrected, for valve seats that can't be repaired, please replace it with new ones. The coaxiality tolerance for repair or replacement of seat and guide is less than 0.03mm.

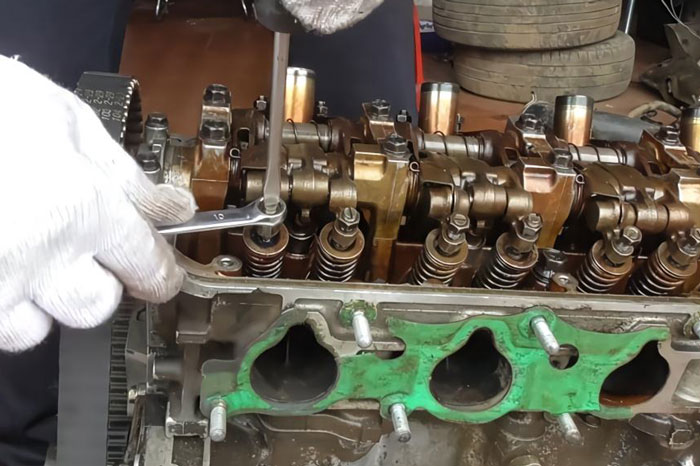

4、 The valve and the seat are gently ground to ensure the valve sealing. The contact part between the valve seat and the valve cone surface should be in the lower middle of valve cone. If the valve and seat are poorly sealed, it will cause engine power loss and early valve damage.

5、 After grinding, clean the abrasive with kerosene, lubricate the valve stem and the guide with clean engine oil, then install valve.

6、 Install new valve oil seal.

Previous: AUTOMECHANIKA SHOW